CNC Machining mu zigawo zamkuwa zachipatala

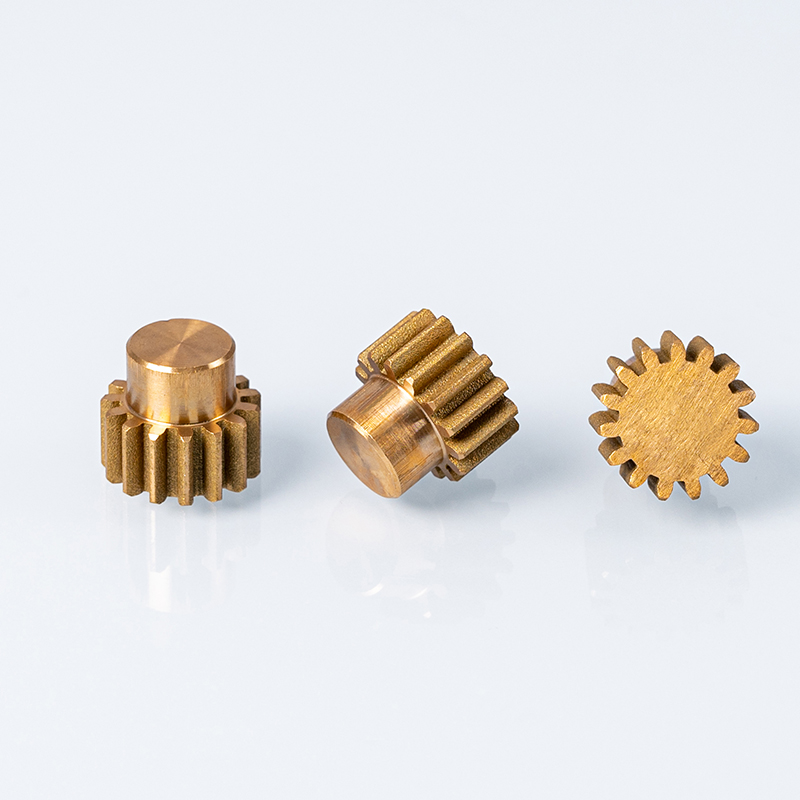

Kufotokozera kwa magawo a makina a CNC okhala ndi Copper Material

Mkuwa umakhalanso wopanda maginito komanso wosayaka, zomwe zimapangitsa kuti zikhale zoyenera kugwiritsidwa ntchito pazida zamankhwala zomwe zimakumana ndi mafunde amagetsi kapena minda yothamanga kwambiri. Copper imalimbananso ndi dzimbiri, zomwe zimapangitsa kukhala chisankho chabwino pazida zamankhwala zomwe zimayikidwa m'madzi kapena zakumwa zina. Makina a CNC mumkuwa amalola kupanga magawo ovuta, ovuta komanso olondola kwambiri komanso olondola. Ziwalo zamkuwa zimatha kupangidwa molingana ndi zomwe zanenedwa komanso kulolerana, kuwonetsetsa kuti zida zamankhwala ndizotetezeka komanso zothandiza.

1. Zida Zamkuwa: C110 (99.9% Copper)

2. Njira: CNC Machining

3. Kulekerera: +/-0.01mm

4. Malizitsani: Zachilengedwe 5. Kugwiritsa ntchito: Kugwiritsidwa ntchito pamagetsi, magetsi, kuunikira ndi mafakitale ena.

Ubwino wa CNC Machining Copper

CNC Machining mkuwa amapereka ubwino wambiri, monga mwatsatanetsatane mkulu ndi kulondola, kwambiri mphamvu ndi kulemera chiŵerengero, matenthedwe wabwino ndi magetsi madutsidwe, kukana dzimbiri kukana poyerekeza ndi zitsulo zina, dimensional bata pa osiyanasiyana kutentha osiyanasiyana, kuchepetsa makina nthawi chifukwa malleability ake ndi mosavuta machinability.

1. Mphamvu zapamwamba komanso zolimba - Mkuwa ndi chinthu cholimba kwambiri ndipo chimatha kupirira kutentha, kuthamanga ndi kuvala. Izi zimapangitsa kukhala chisankho chabwino kwambiri pakugwiritsa ntchito makina a CNC, chifukwa chitha kugwiritsidwa ntchito m'njira zosiyanasiyana ndipo imatha kupirira zovuta zobwerezabwereza, zolondola kwambiri.

2. Wabwino matenthedwe madutsidwe - Mkuwa kwambiri matenthedwe madutsidwe zimapangitsa kukhala abwino kwa CNC Machining ntchito amafuna mwatsatanetsatane kudula ndi kubowola ntchito. Izi zimatsimikizira kuti chomalizidwacho chidzakhala ndi mlingo wapamwamba kwambiri wolondola komanso wolondola.

3. High magetsi madutsidwe - Mbali imeneyi imapangitsa mkuwa kukhala zinthu zabwino CNC Machining ntchito amafuna mawaya magetsi kapena zigawo zikuluzikulu.

4. Zotsika mtengo - Copper nthawi zambiri imakhala yotsika mtengo kuposa zitsulo zina, zomwe zimapangitsa kukhala chisankho chabwino kwambiri cha ma CNC machining mapulojekiti omwe amafunikira magawo ambiri kapena zigawo zikuluzikulu.

5. Zosavuta kugwira ntchito - Mkuwa ndi chinthu chosavuta kugwira ntchito, cholola kupanga mofulumira komanso kulondola kwambiri.

Momwe Copper mu CNC Machining magawo

CNC machining mbali zamkuwa kumaphatikizapo kugwiritsa ntchito zida zodulira mwatsatanetsatane monga mphero zomaliza kuchotsa zinthu kuchokera ku workpiece molingana ndi njira yokonzedwa. Kukonzekera kwa makina a CNC kumachitika kudzera mu pulogalamu yothandizidwa ndi makompyuta (CAD) ndipo kenako imasamutsidwa kumakina kudzera pa G code, yomwe imalola kuti igwire ntchito iliyonse. Ziwalo zamkuwa zimatha kubowoledwa, kupedwa kapena kutembenuzika kutengera ntchito. Madzi opangira zitsulo amagwiritsidwanso ntchito nthawi zambiri pakupanga makina a CNC, makamaka akamagwira zitsulo zolimba ngati mkuwa zomwe zimafunikira mafuta owonjezera.

CNC machining mkuwa mbali ndi ndondomeko Machining ntchito makompyuta manambala ankalamulira makina (CNC) kupanga zinthu zamkuwa. Mkuwa umagwiritsidwa ntchito zosiyanasiyana CNC ntchito kuphatikizapo prototyping, nkhungu, mindandanda yamasewera, ndi mapeto ntchito mbali.

CNC Machining mkuwa amafuna kugwiritsa ntchito mapulogalamu apadera ndi makina CNC amene ali ndi zida zoyenera kudula molondola ndi kuumba zinthu. Njirayi imayamba ndikupanga mtundu wa 3D wa gawo lomwe mukufuna mu pulogalamu ya CAD. Mtundu wa 3D umasinthidwa kukhala chida, chomwe ndi malangizo omwe amakonza makina a CNC kuti apange mawonekedwe omwe akufuna.

Makina a CNC ndiye amadzazidwa ndi zida zoyenera, monga mphero zomaliza ndi zobowola, ndipo zinthuzo zimayikidwa mu makinawo. Zinthuzo zimapangidwira molingana ndi njira yopangira zida ndipo mawonekedwe omwe akufuna amapangidwa. Ntchito yokonza makina ikatha, gawolo limawunikiridwa kuti liwonetsetse kuti likukwaniritsa zofunikira. Ngati ndi kotheka, gawolo limatsirizidwa ndi njira zosiyanasiyana zopangira makina monga kupukuta ndi kupukuta.

Zomwe makina a CNC angagwiritse ntchito Copper

CNC makina amkuwa angagwiritsidwe ntchito pazinthu zosiyanasiyana, kuphatikizapo zida zamagetsi ndi zolumikizira, zida zamagalimoto zolondola kwambiri, zida zamlengalenga, zida zamankhwala, misonkhano yovuta yamakina ndi zina zambiri. Ziwalo zamakina a Copper CNC nthawi zambiri zimakutidwa ndi zitsulo zina kuti zipititse patsogolo madulidwe kapena kukana kuvala.

CNC Machining mbali mkuwa angagwiritsidwe ntchito zosiyanasiyana ntchito, kuphatikizapo zolumikizira magetsi, nyumba housings, kutentha exchangers, zigawo zamadzimadzi mphamvu, zigawo zikuluzikulu structural, ndi zigawo kukongoletsa. Magawo amkuwa ndi abwino kwa CNC Machining chifukwa champhamvu yake yamagetsi ndi matenthedwe, komanso kukana kwake kwa dzimbiri. CNC Machining mkuwa angagwiritsidwenso ntchito kupanga akalumikidzidwa zovuta ndi mbali ndi kulolerana ndendende.

Ndi mankhwala amtundu wanji omwe ali oyenera CNC machining mbali za Copper

The abwino kwambiri padziko mankhwala CNC Machining mkuwa mbali anodizing. Anodizing ndi njira yomwe imaphatikizapo electro mankhwala kuchitira zitsulo ndi kupanga okusayidi wosanjikiza pamwamba pa zinthu zomwe kumawonjezera kuvala kukana ndi dzimbiri chitetezo. Ikhoza kugwiritsidwanso ntchito popereka zokongoletsera zokongoletsera monga mitundu yowala, mapeto a matte kapena matani owala.

Ma aloyi amkuwa nthawi zambiri amathandizidwa ndi plating ya nickel ya electroless, anodizing, ndi passivation kuteteza pamwamba kuti zisawonongeke komanso kuvala. Njirazi zimagwiritsidwanso ntchito kupititsa patsogolo kukongola kwa gawolo.

Ntchito:

Makampani a 3C, zokongoletsera zowunikira, zida zamagetsi, zida zamagalimoto, mbali za mipando, chida chamagetsi, zida zamankhwala, zida zodzichitira zanzeru, zida zina zoponya zitsulo.