Maluso athu otembenuza CNC

From prototyping to full production runs. Our wide range of CNC lathes and turning centers will allow you to produce highly accurate, high quality parts to meet even your most complex requirements. Can’t decide which machining process is best for you? Just send us drawing by email:rfq@lairun.com.cn

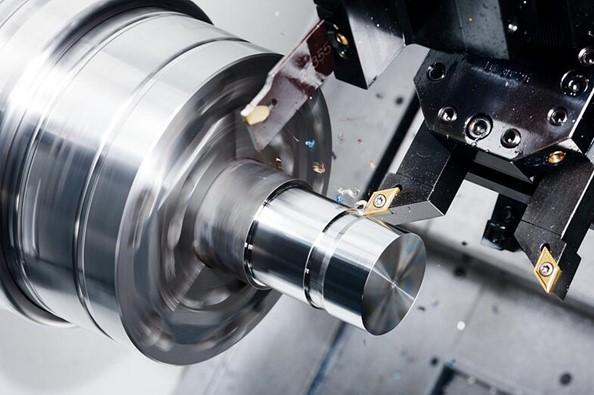

Chithunzi cha CNC

Makina otembenuza a CNC amatha kupereka magawo otsika mtengo a ma geometries osavuta a cylindrical. Njira yathu yosinthira CNC imapanga ma prototypes ndi zida zogwiritsira ntchito kumapeto mwachangu ngati tsiku limodzi. Timagwiritsa ntchito CNC lathe yokhala ndi zida zamoyo kotero kuti mawonekedwe ngati ma axial ndi ma radial mabowo, ma flats, grooves, ndi mipata amatha kupanga makina.

Kutembenuza kwa CNC nthawi zambiri kumagwiritsidwa ntchito:

Ma prototypes ogwira ntchito ndi magawo omaliza

Magawo okhala ndi ma cylindrical

Magawo okhala ndi mabowo a axial ndi radial, ma flat, grooves, ndi mipata

Magawo okhala ndi ma shafts, mavavu, mphete zotsekera ndi silinda.

Timapereka mayankho mwachangu kuti tiwonetsetse kuti gawo lanu likukomedwa ndi njira yosinthira CNC ndikukwaniritsa zomwe mukufuna. Wopanga wathu amatha kupereka zitsulo zapamwamba kwambiri ndi pulasitiki CNC kutembenuza magawo kuti prototyping mofulumira. wer ndi mphamvu zothamanga zomwe zimakhudza mitundu ya magawo omwe angapangidwe mwachuma pa izo.

Kodi CNC Turning ndi chiyani? Kodi Imagwira Ntchito Motani?

●Computer Numerical Control (CNC) kutembenuza ndi njira yopangira yomwe imagwiritsa ntchito lathe kuti ipange zolondola, zamtundu wazinthu zochokera kuzinthu zosiyanasiyana, monga zitsulo, pulasitiki, ndi aluminiyamu. Makina a lathe amazungulira chogwirira ntchito pomwe chida chodulira chimachipanga kukula ndi mawonekedwe omwe mukufuna.

●Kutembenuza kwa CNC kumayamba ndi mapangidwe opangidwa pogwiritsa ntchito pulogalamu ya Computer-Aided Design (CAD). Mapangidwewo amasinthidwa kukhala code yomwe CNC lathe imatha kuwerenga ndikutsata. Wogwira ntchitoyo amayika makinawo pokweza chogwirira ntchito mu lathe ndikuyika zida zofunika.

● Makinawo akakonzeka, pulogalamu ya CNC imakwezedwa, ndipo woyendetsa akuyamba ntchitoyi. CNC lathe imazungulira chogwirira ntchito pa liwiro lalikulu pomwe chida chodulira chimayenda motsatira zinthuzo, kuchotsa zinthu zochulukirapo mpaka gawolo lifika pa mawonekedwe ndi kukula kwake.

● Kutembenuza kwa CNC kumapereka maubwino ambiri kuposa kutembenuza pamanja. Choyamba, kulondola komanso kulondola kwa kutembenuka kwa CNC ndikokwera kwambiri kuposa kutembenuza pamanja. Izi zili choncho chifukwa makina a CNC adakonzedwa kuti azitsatira momwe amapangidwira ndendende, pomwe kutembenuza pamanja kumadalira luso la wogwiritsa ntchitoyo komanso luso lake.

● Kuphatikiza apo, kutembenuka kwa CNC ndikothamanga kwambiri kuposa kutembenuza pamanja. Ndi CNC lathe, wogwiritsa ntchito amatha kukhazikitsa ndikuyendetsa magawo angapo nthawi imodzi, zomwe zimapangitsa kuti pakhale kuchuluka kwambiri. Kutembenuza kwa CNC kumakhalanso kothandiza kwambiri, ndikuwononga zinthu zochepa komanso kutsika mtengo kwa ogwira ntchito.

● Pa malo athu ogulitsira makina a CNC, timapereka ntchito zotembenuza mofulumira kwambiri za CNC. Zipangizo zathu zamakono komanso ogwira ntchito odziwa zambiri amatilola kuti tipange zida zodzikongoletsera molondola komanso mwachangu. Timakhazikika pakupanga ma prototyping ndipo timatha kuthana ndi magawo ang'onoang'ono ndi akulu.

● Pomaliza, kutembenuka kwa CNC ndi njira yabwino kwambiri komanso yolondola yopangira zinthu zomwe zimatha kupanga zida zachikhalidwe mwachangu komanso mwatsatanetsatane mwapadera. Kaya mukufuna fanizo limodzi kapena kupanga kwakukulu, kutembenuka kwa CNC ndi chisankho chabwino kwambiri pazosowa zanu zopanga.

Mitundu ya CNC Lathes

Pali mitundu yambiri ya lathes, koma ambiri ndi 2-olamulira CNC lathes ndi Swiss-mtundu lathes. Ma lathe amtundu wa Swiss ndi apadera chifukwa zinthu zomwe zimadyetsedwa zimadyedwa kudzera mu kalozera, zomwe zimalola chidacho kuti chidulire pafupi ndi nsonga yothandizira, zomwe zimawapangitsa kukhala ofunikira kwambiri pazigawo zazitali, zowonda za CNC lathe ndi micromachining. Ma lathe ena amtundu wa Swiss amabweranso ali ndi mutu wachiwiri wa chida chomwe chimagwira ntchito ngati aMtengo CNC, kuwalola kuchita ntchito zingapo zamakina popanda kusuntha chogwirira ntchito ku makina ena. Izi zimapangitsa kuti ma lathe amtundu waku Switzerland akhale okwera mtengo kwambiri pamagawo ovuta omwe ali ndi ntchito za CNC lathe.

Mitundu ya CNC Lathes

MongaZithunzi za CNC, CNC lathes akhoza kukhazikitsidwa mosavuta kwa kubwereza kwapamwamba, zomwe zimawapangitsa kukhala abwino kwa chirichonse kuchokera ku prototyping mofulumira mpaka kupanga otsika komanso apamwamba kwambiri. Malo otembenuzira a Multi-axis CNC ndi ma lathe amtundu wa Switzerland amalola kuti pakhale makina angapo pamakina amodzi. kuwapanga kukhala njira yotsika mtengo kwa ma geometries ovuta omwe angafune makina angapo kapena kusintha kwa zida mu mphero yachikhalidwe ya CNC.

Mitundu ya CNC Lathes

●Ngati mukufuna zida zapamwamba, zokonda mwachangu, ntchito zathu zotembenuza za CNC ndizabwino kwambiri. Kumalo athu ogulitsira makina a CNC, timagwiritsa ntchito zida zamakono komanso ogwira ntchito odziwa zambiri kuti apange magawo olondola ndi liwiro lapadera komanso molondola.

● Ntchito zathu zotembenukira mwachangu za CNC ndizoyenera kupanga ma prototyping komanso kupanga ma voliyumu otsika mpaka apakatikati. Timakhazikika pakupanga zida zamitundu yosiyanasiyana, kuphatikiza zitsulo, pulasitiki, ndi matabwa. Timapereka zomaliza zosiyanasiyana, kuphatikiza zotayira anodized ndi PTFE zokutira.

● Njira yathu yosinthira CNC imayamba ndi mapangidwe opangidwa pogwiritsa ntchito mapulogalamu a CAD. Mapangidwewo amasinthidwa kukhala code yomwe CNC lathe imatha kuwerenga ndikutsata. Wogwira ntchitoyo amayika makinawo pokweza chogwirira ntchito mu lathe ndikuyika zida zofunika.

● Makinawo akakonzeka, woyendetsa akuyamba ntchitoyo. CNC lathe imazungulira chogwirira ntchito pa liwiro lalikulu pomwe chida chodulira chimayenda motsatira zinthuzo, kuchotsa zinthu zochulukirapo mpaka gawolo lifika pa mawonekedwe ndi kukula kwake.

● Ntchito zathu zotembenukira mwachangu za CNC zimapereka maubwino ambiri. Choyamba, titha kupanga zidziwitso mwachangu, ndi nthawi yocheperako kuposa njira zopangira zachikhalidwe. Kuphatikiza apo, kulondola kwathu ndi kulondola kwathu sikungafanane, chifukwa cha zida zathu zamakono komanso ogwiritsa ntchito odziwa zambiri.

● Timaperekanso chithandizo chabwino kwambiri kwa makasitomala ndi chithandizo panthawi yonseyi. Kuchokera pakupanga mpaka kubereka, timagwira ntchito limodzi ndi makasitomala athu kuti atsimikizire kuti alandila magawo apamwamba kwambiri munthawi yochepa kwambiri.

Pomaliza, ntchito zathu zotembenuza mwachangu za CNC ndi chisankho chabwino kwambiri pazosowa zanu zopanga. Kaya mukufuna chojambula chimodzi kapena chiwongolero chachikulu, titha kupereka zida zodziwikiratu mwachangu komanso mwatsatanetsatane mwapadera.

Kuthekera kwakukulu kwa CNC kutembenuka

| Gawo la kukula kwa malire | Magawo a metric | Magawo a Imperial |

| Kuchuluka kwa gawo lalikulu | 431 mm | 17 mu |

| Utali wa gawo lalikulu | 990 mm | 39 mu |

| Kugwedezeka kwakukulu pagalimoto | 350 mm | 13.7 ku |

| Zolemba malire spindle kudutsa-dzenje | 40 mm | 1.5 mu |

Kupaka Powder

Nawu mndandanda wazinthu zathu zamakina a CNC zomwe zilipo.

CNC Zitsulo

| Pulasitiki | Pulasitiki Wolimbikitsidwa |

| ABS | Garolite G-10 |

| Polypropylene (PP) | Polypropylene (PP) 30% GF |

| Nylon 6 (PA6 /PA66) | Nayiloni 30% GF |

| Delrin (POM-H) | FR-4 |

| Acetal (POM-C) | PMMA (Akriliki) |

| Zithunzi za PVC | PEEK |

| Zithunzi za HDPE | |

| UHMW PE | |

| Polycarbonate (PC) | |

| PET | |

| PTFE (Teflon) |

Kulekerera

Timatsatira miyezo ya ISO 2768 ya CNC Machining.

| Malire a kukula mwadzina | Pulasitiki (ISO 2768- m) | Zitsulo (ISO 2768- f) |

| 0.5mm* mpaka 3mm | ± 0.1mm | ± 0.05mm |

| Kupitilira 3mm mpaka 6mm | ± 0.1mm | ± 0.05mm |

| Kupitilira 6mm mpaka 30mm | ± 0.2mm | ± 0.1mm |

| Kupitilira 30mm mpaka 120mm | ± 0.3mm | ± 0.15mm |

| Kupitilira 120mm mpaka 400mm | ± 0.5mm | ± 0.2mm |

| Kupitilira 400mm mpaka 1000mm | ± 0.8mm | ± 0.3mm |

| Kupitilira 1000mm mpaka 2000mm | ± 1.2mm | ± 0.5mm |

| Kupitilira 2000mm mpaka 4000mm | ± 2 mm |

- Chonde onetsani momveka bwino kulolerana kwa miyeso yomwe ili pansi pa 0.5mm pazojambula zanu zaukadaulo.

CNC kutembenuza malangizo kamangidwe

Gome ili m'munsili likufotokozera mwachidule zomwe zikulimbikitsidwa komanso zotheka mwaukadaulo pazinthu zomwe zimakumana ndi magawo amakina a CNC.

| Mbali | Kukula kovomerezeka | Kukula kotheka |

| Min. kukula kwake | Ø 2.5 mm | Ø 0.5 mm |

| M'mphepete mwamkati | ku 8 mm | R0.25 mm |

| Kuchuluka kwa khoma | 0.8 mm (zazitsulo) | 0.5 mm (zazitsulo) |

| 1.5 mm (ya mapulasitiki) | 1.0 mm (ya mapulasitiki) | |

| Mabowo | Diameter: makulidwe amtundu wabowola | M'mimba mwake: Ø 0.5 mm |

| Kuzama: 4 x m'mimba mwake | Kuzama: 10 x m'mimba mwake | |

| Ulusi | Kukula: M6 kapena kupitilira apo | Kukula: M2 |

| Utali: 3 x awiri |